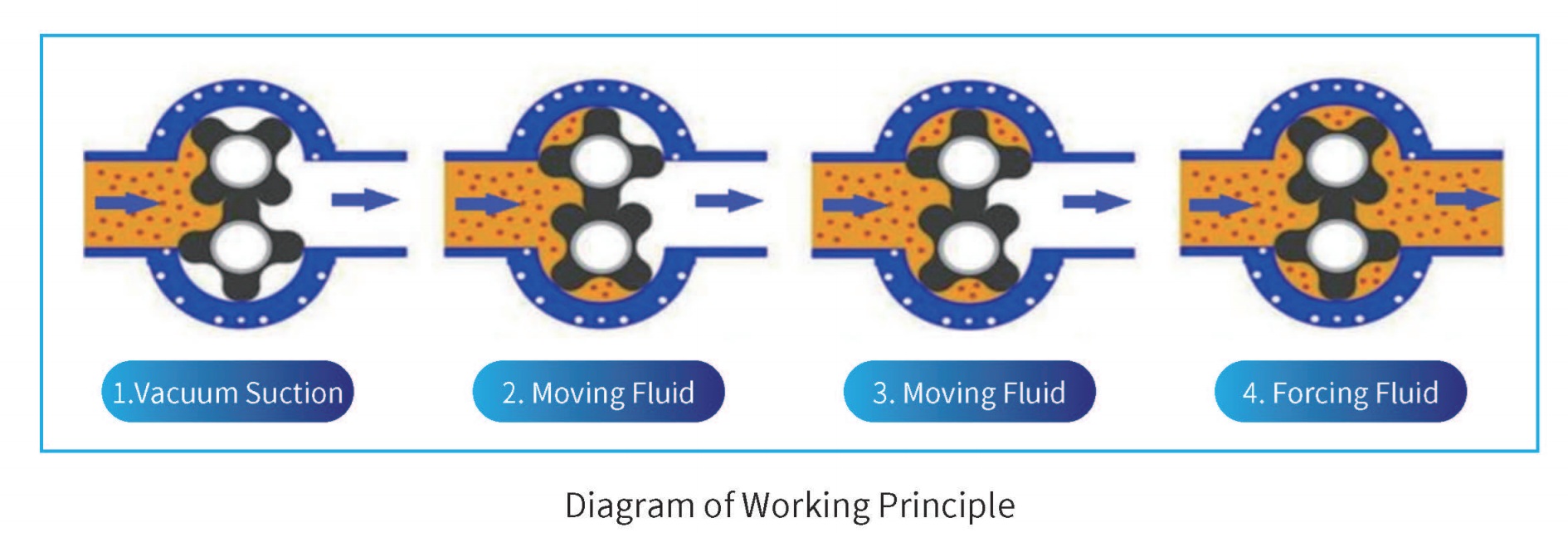

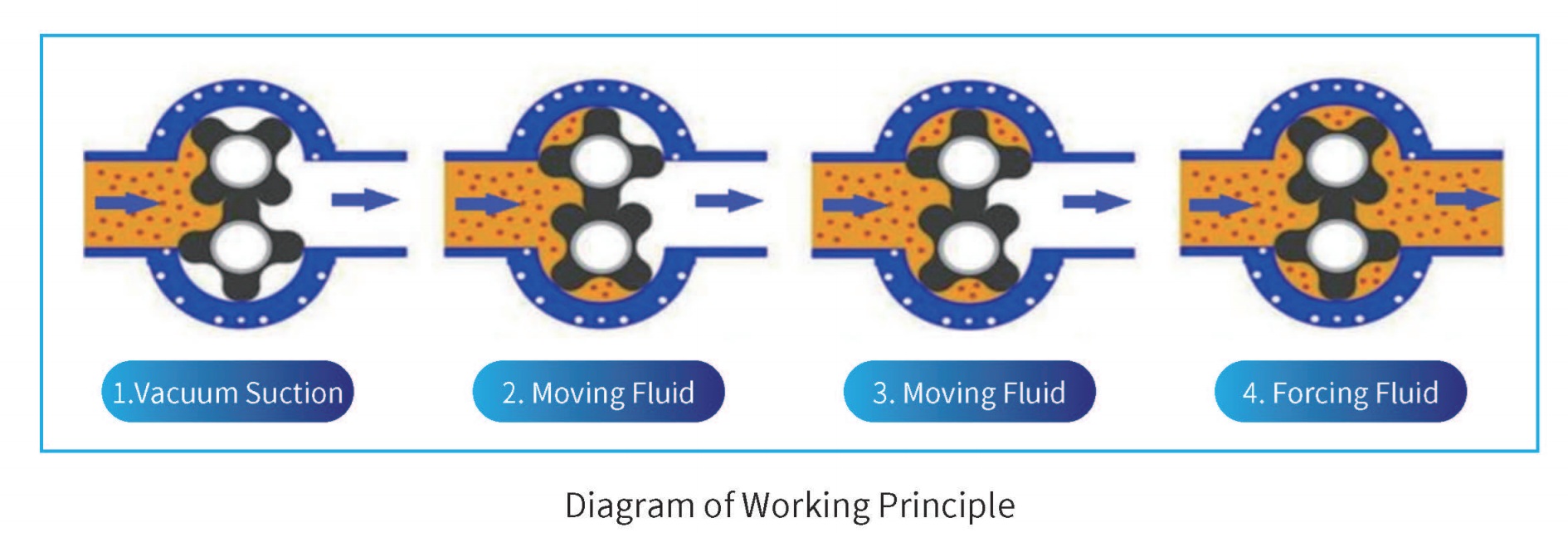

The Rotary Lobe Pump is an internationally advanced technology rotary displacement pump that combines the advantages of centrifugal pumps and screw pumps. It consists of a set of rotors that rotate synchronously in reverse, gradually increasing the volume of the inlet chamber to form negative pressure, and then sucking in the material to be transported to form sealed chambers. The source continuously sucks in the pump chamber to gradually form pressure, and the medium is continuously discharged from the pump chamber.

Advantages of LobePro rotary pump compared to peers:

1. Strong vacuum suction ability, with a maximum self-priming capacity of 8.5 meters;

2. Transport high solid content media, up to 80% (density ratio);

3. Can transport high viscosity colloids with a maximum viscosity of 100000 centipoise;

4. The maximum allowable passing size is 70mm;

5. The gap can be adjusted twice, which can save 70% of spare parts costs

6. The container machine seal is designed specifically for harsh working conditions, extending its lifespan by more than 50%.

7 occupies less space than screw pumps, and the pump head occupies one-third of the space of screw pumps;

8. It can be operated in both forward and reverse directions, with one pump for dual use;

9. Not sensitive to dry operation and cavitation;

LobePro rotary pumps are widely used in various fields such as municipal environmental protection, food and beverage, lithium-ion new energy, petrochemicals, metallurgy and mining, kitchen waste treatment, agriculture and animal husbandry, transportation, fire and drainage, papermaking and pulp.

Consult Now

Consult Now