National Hotline

+86 400 888 9412

Consult Now

Consult Now

The main principles of MBR membrane technology include the following aspects:

1. Bioreactor: The MBR membrane process uses a bioreactor as the core component of wastewater treatment. In a bioreactor, an appropriate amount of microorganisms are added to utilize their metabolic activity to degrade organic matter into inorganic matter. Meanwhile, microorganisms can also adsorb and engulf suspended solids and colloidal substances in water.

2. Membrane separation: The MBR membrane process uses microporous membranes as the separation medium to separate water and microorganisms in the bioreactor. Microporous membranes have smaller pore sizes and can intercept suspended solids, colloidal substances, and microorganisms in water, while allowing water molecules to pass through. Through membrane separation, efficient solid-liquid separation and microbial retention can be achieved.

3. Membrane fouling control: Due to the easy occurrence of membrane fouling during membrane separation, which affects membrane flux and separation efficiency, a series of measures need to be taken to control membrane fouling. Common control methods include membrane surface cleaning, chemical cleaning, gas aeration, and membrane aeration.

MBR membrane technology has the advantages of good treatment effect, small footprint, and high effluent quality, and is widely used in urban sewage treatment, industrial wastewater treatment, and water resource recovery.

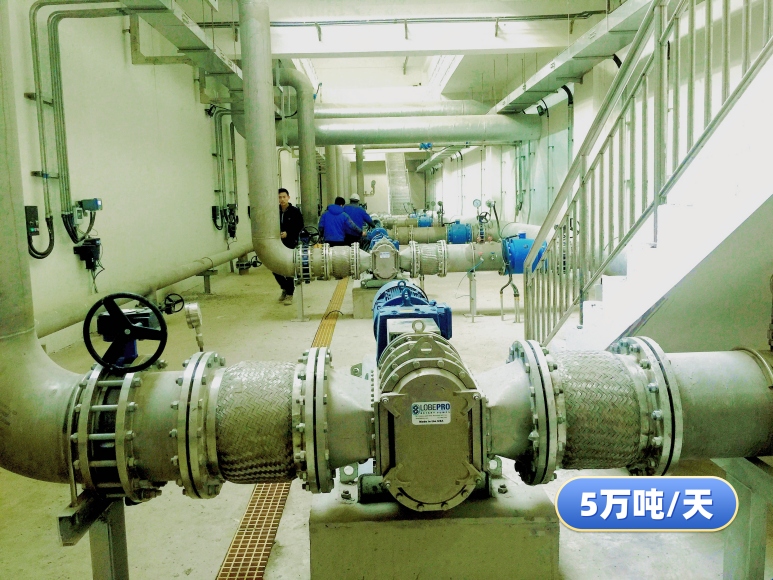

As a membrane water production and backwashing pump, as well as a drug washing pump, LobePro rotary pump has strong anti cavitation ability. It can perform both water production and backwashing functions in one pump, with stable operation, adjustable flow rate, and minimal maintenance. It has nearly 20 successful performances in China.

This MBR project has a capacity of 50,000 tons per day, with 8 X350m3/h membrane water production and backwash rotary pumps installed in 2016

This MBR project has a capacity of 120,000 tons per day, with 12 500m3/h membrane water production and backwash rotary pumps installed in 2018